About Fulong

In the modern defense industry, from ground equipment to aerial vehicles, and from weapon systems to communication devices, every component must possess exceptional stability, strength, and precision. These stringent requirements make defense manufacturing not only a technical discipline but also a critical task related to national security and strategic deployment.

As a specialist in high-precision machining technology, Fulong Technology Co., Ltd. is dedicated to providing the defense industry with reliable, accurate, and high-performance component manufacturing services.

Strict Standards in Defense Manufacturing

Components for military equipment often must withstand extreme temperatures, powerful impacts, high vibrations, and prolonged operation. The requirements for materials and machining precision far exceed those of general industries. For example, precision linkages in missile control systems, drivetrain parts in tactical vehicles, or high-precision housings for military optical devices — even the smallest deviation in these components can affect overall system performance and safety.

The machining technologies provided by Fulong Technology

are the ideal solutions to meet these high-level requirements.

High-Precision CNC Technology Applied in the Defense Sector

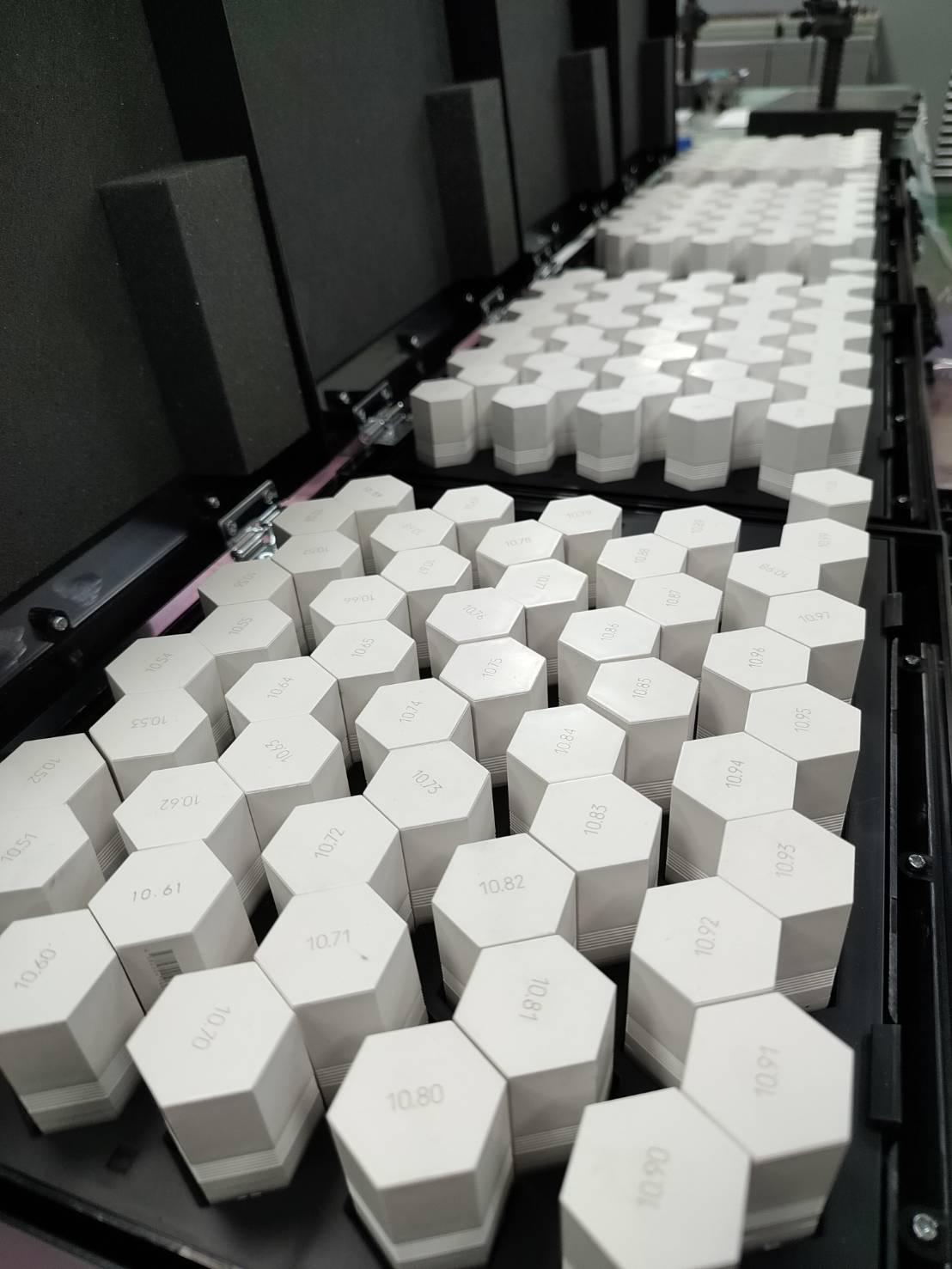

Fulong Technology is equipped with multiple advanced CNC milling machines, CNC lathes, turn-mill centers, broaching machines, and laser engraving machines. We handle high-strength metals commonly used in military applications, such as titanium alloys, stainless steel, and aluminum alloys, while supporting complex structures and multi-axis machining requirements.

Our advantages include

01

Micron-level precision meeting the high tolerance requirements of military components

02

Stable and consistent mass production capabilities, ideal for long-term contracts and repeat manufacturing

03

Multi-functional integrated machining effectively reduces processing steps and errors, enhancing both efficiency and quality.

Additionally, we support small-batch customized development for defense projects, assisting R&D teams in rapidly completing design validation and prototype production.

Project Experience and Confidentiality Assurance

Fulong Technology fully understands the defense industry's critical emphasis on data confidentiality and machining security. We have established comprehensive internal management systems and strictly enforce confidentiality agreements and data control measures to ensure all client information is developed and manufactured in a secure environment.

In past collaborations, we have supported the development of precision connectors for military communication equipment, metal housings for fire control systems, and high-pressure resistant, corrosion-proof airtight components. All these projects were successfully delivered and highly praised.

Precision machining empowers innovation in the defense industry.

Modern warfare is trending toward miniaturization, intelligence, and automation, demanding military equipment to feature higher precision and more compact key components. Fulong Technology actively invests in advanced technologies and R&D capabilities, collaborating closely with the defense industry to develop precision parts with strategic value for the future.

We focus not only on the machining process itself but also place strong emphasis on material selection, stress analysis, and the overall operational environment. Our comprehensive technical support covers the entire process—from design participation to final delivery.

Co-create an Unbreakable Defense System with Fulong Technology.

In the defense industry, every detail matters.

Fulong Technology Co., Ltd. leverages its solid technical expertise, advanced machining equipment, and rigorous quality control processes to provide reliable precision parts manufacturing services for the military sector.

If you're seeking a partner with confidentiality, stability, and high-precision machining capabilities, Fulong Technology is your most trusted choice.