Surface Finishing

In addition to precision dimensional processing, the final appearance, durability and function of parts often depend on the subsequent surface treatment process.

Fulong has long cooperated with many professional surface treatment manufacturers and can integrate and execute a variety of surface processing projects, such as anodizing, painting, sandblasting, passivation, electroplating, chemical treatment and label printing, etc., to help customers get everything from processing to appearance in one go.

Each product, use and material has different requirements for surface treatment. We can arrange the appropriate process according to the material of the part and the customer's appearance/corrosion resistance/marking requirements, and ensure stable process, clear delivery date and consistent quality.

Whether it is functional processing or brand identification, we can assist in overall arrangement and quality tracking, simplify your supply chain communication process and reduce the risk of errors.

From initial OEM to complete product landing, we are your most trusted processing backing.

Service Advantages

Anode

A common surface treatment process for aluminum, providing good corrosion protection and appearance color selection. Suitable for exposed parts or shell parts that require brand identification.

Paint Coating

Powder coating or wet spraying can be selected to improve surface protection and texture. It is often used for the protection and appearance processing of aluminum, steel and plastic materials.

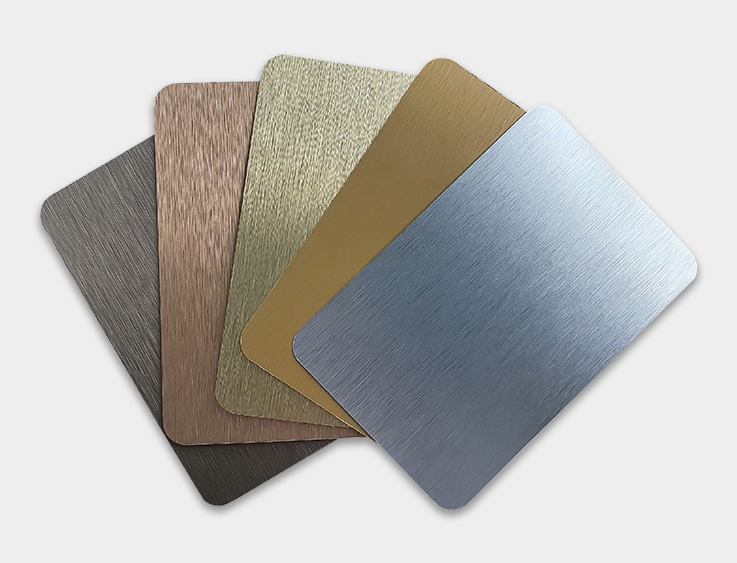

Sandblasting

Surface atomization and homogenization treatment is suitable for metal and plastic materials. It can eliminate micro scratches and provide a good adhesion base. It is often used for anode pretreatment.

Labeling

Product labels and serial number stickers can be made according to needs to provide product traceability and identification functions. It is commonly used in industrial or electronic applications.

Grinding

It is often used for dimensional correction or tolerance compression after secondary processing. It can achieve high precision and excellent surface finish. It is suitable for precision components with large-scale processing or high positioning requirements.