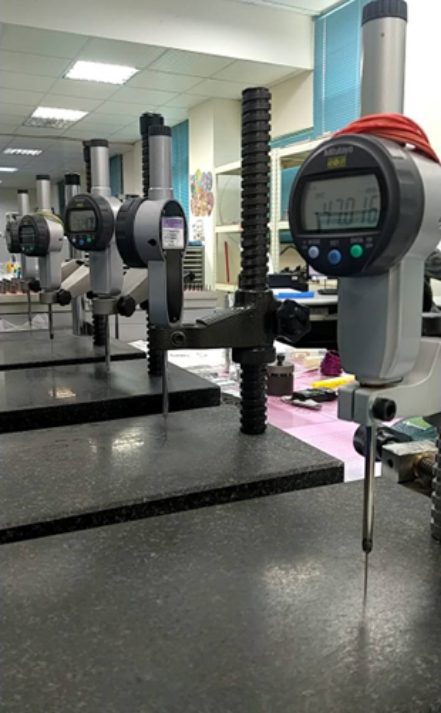

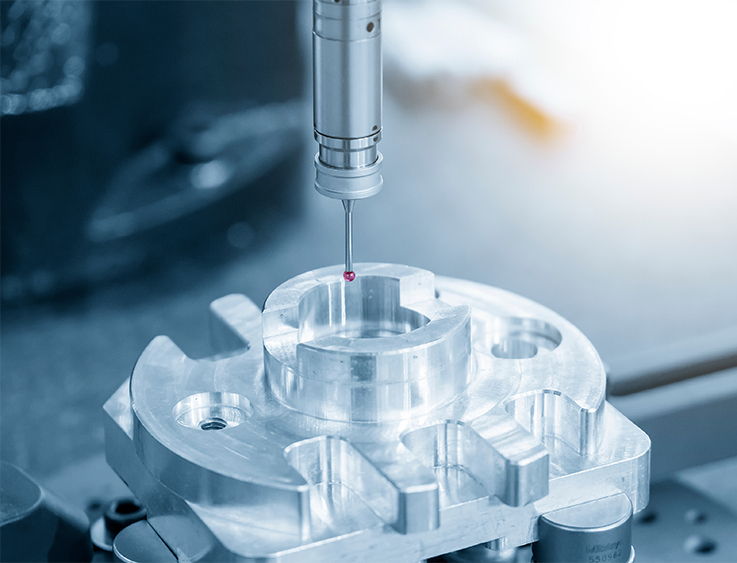

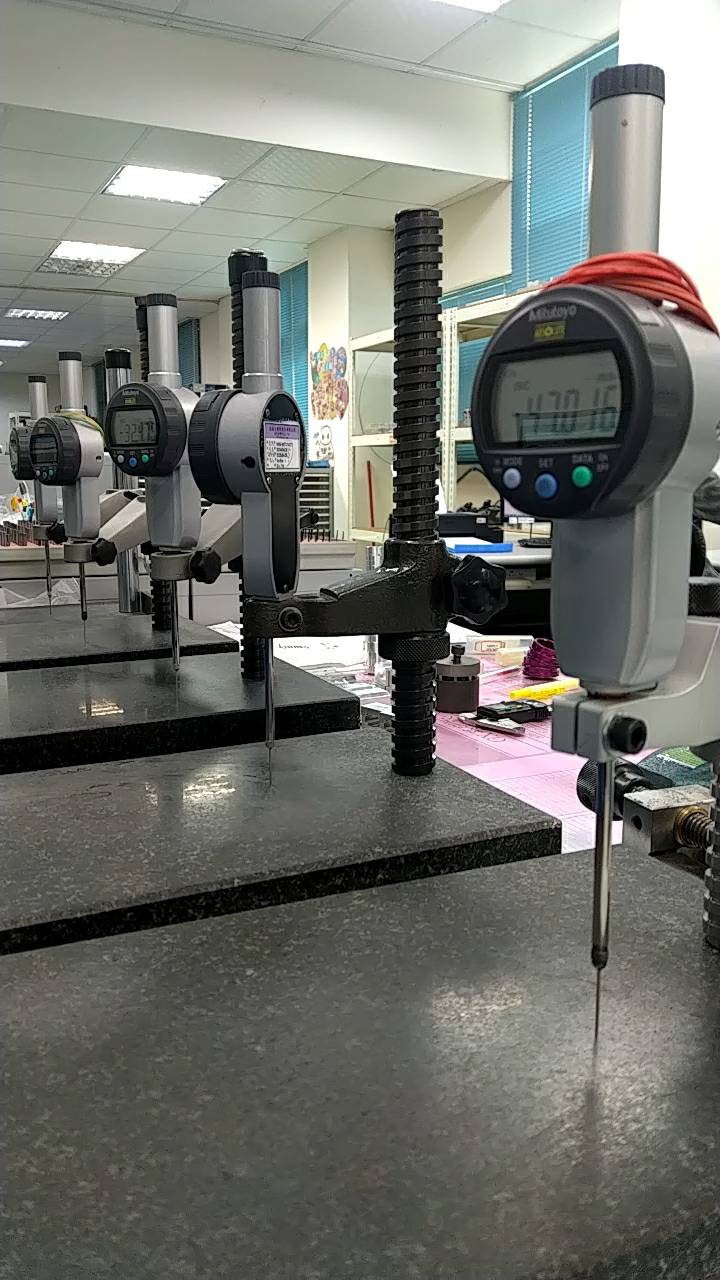

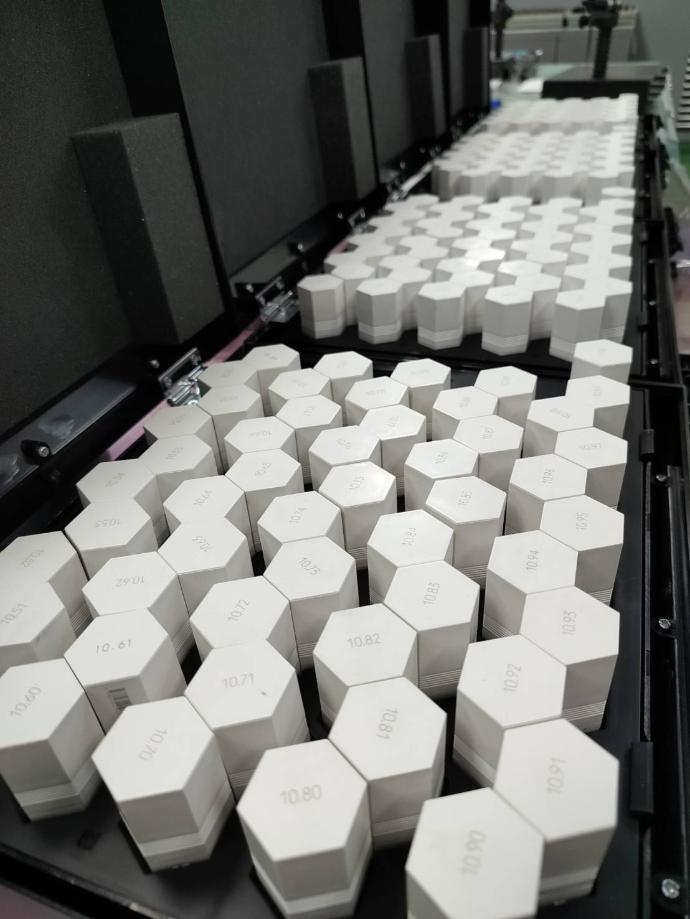

The company has a professional quality management department, which not only conducts basic dimensional inspections, but also introduces the concept of ""length laboratory"" to establish a systematic, traceable and scientific measurement process.

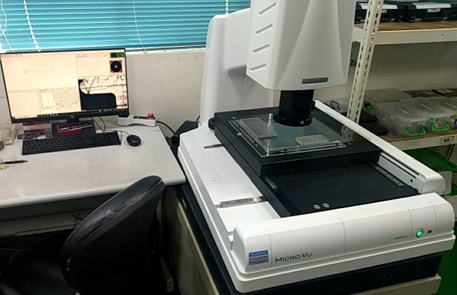

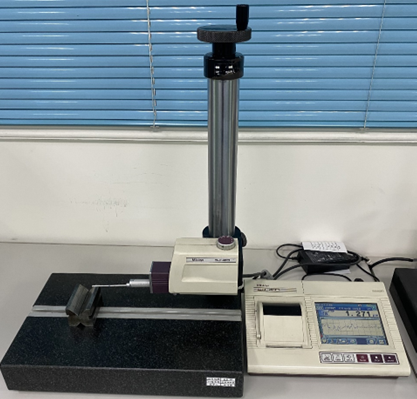

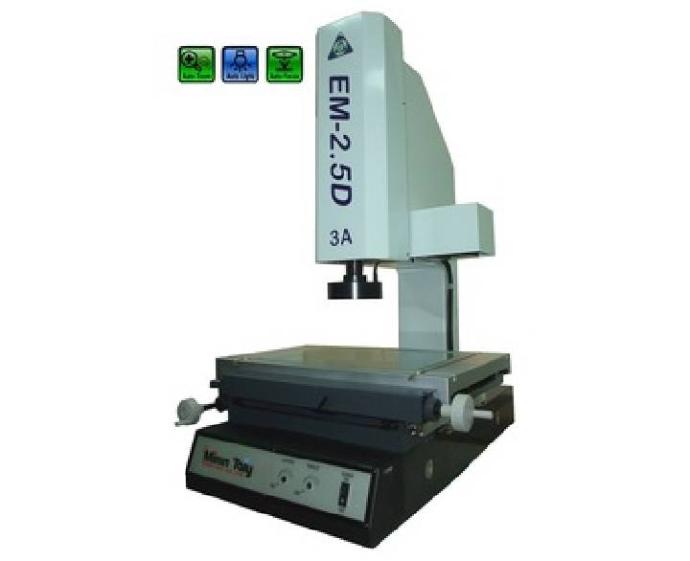

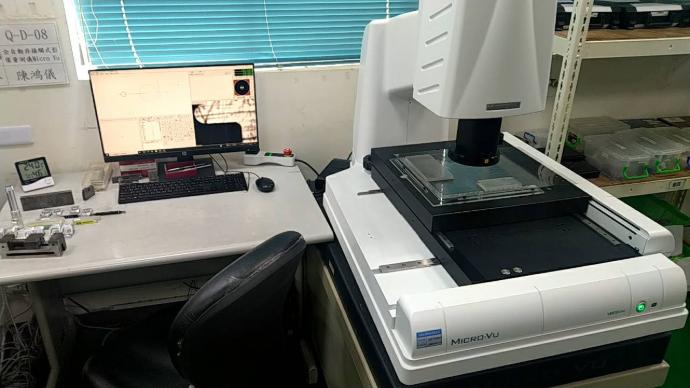

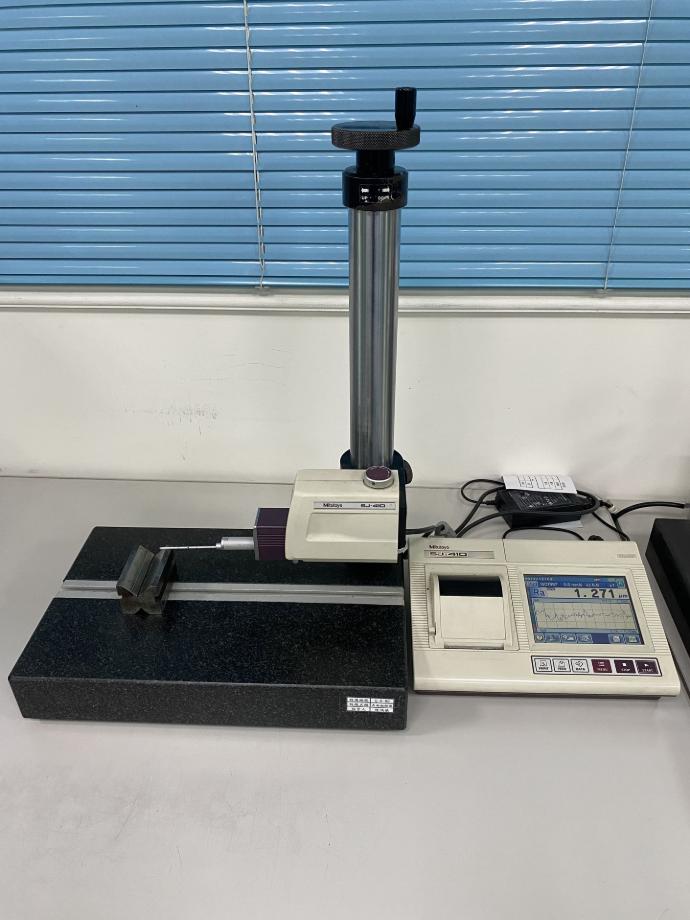

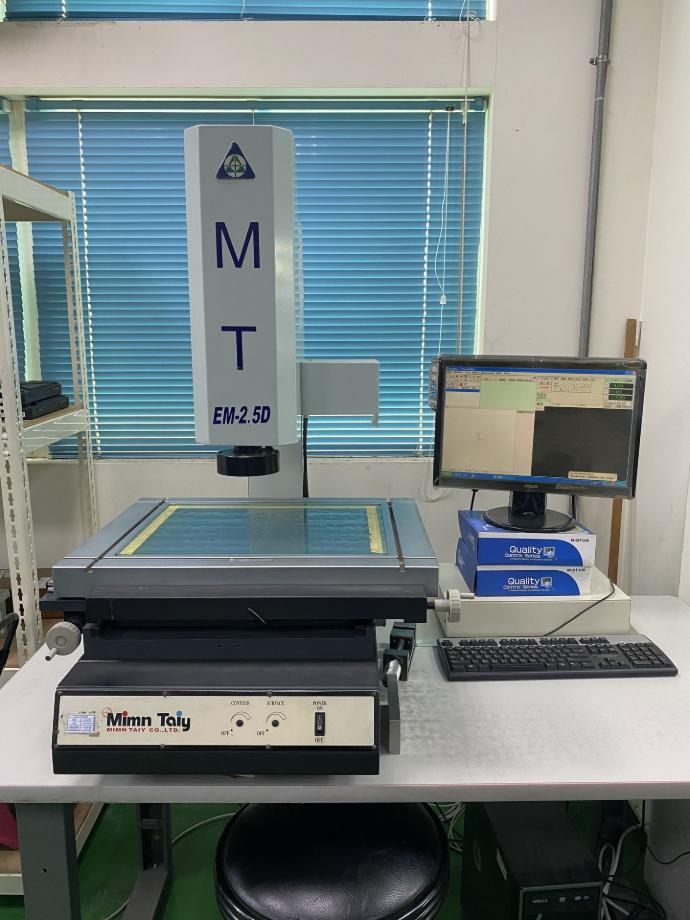

We have advanced equipment such as the German Zeiss three-dimensional measuring instrument (CMM), Micro-Vu automatic optical image measurement system, automatic projector, Mitutoyo surface roughness tester, etc., to ensure that we can conduct comprehensive dimensional and geometric characteristic analysis for high-precision and high-complexity parts. Our measurement procedures comply with relevant ISO standards, and we regularly calibrate the measuring instruments and control the temperature and humidity environment to pursue the accuracy and consistency of the measurement results.

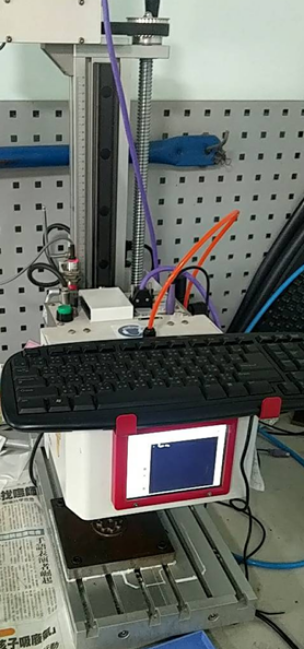

Our philosophy is to make ""measurement"" part of the process rather than an after-the-fact inspection; from pre-processing drawing analysis, fixture design, to process control and final inspection, we regard quality assurance management as the core of the entire manufacturing process, and are committed to providing quality stability that exceeds customer expectations.