Near-Net-Shape Forming

Fulong has been deeply involved in the field of CNC precision machining for many years, and has accumulated rich practical experience and manufacturing coordination capabilities. According to customer product design requirements, we can help connect the complete process from near-net-shape forming to finishing, surface treatment, packaging and shipment.

We have established long-term cooperative relationships with many professional manufacturers, and can arrange various front-end processes including forging, die-casting, plastic injection, stamping, powder metallurgy, etc., and select the most suitable process path according to processing characteristics and back-end requirements.

We understand when to use which initial processing method and how to connect precision CNC processing and measurement verification later.

Customers do not need to contact multiple parties. We can coordinate the cooperation factories, track delivery dates, and integrate specifications for you, turning complex process division of labor into a simple process that can be solved at one window.

Service Advantages

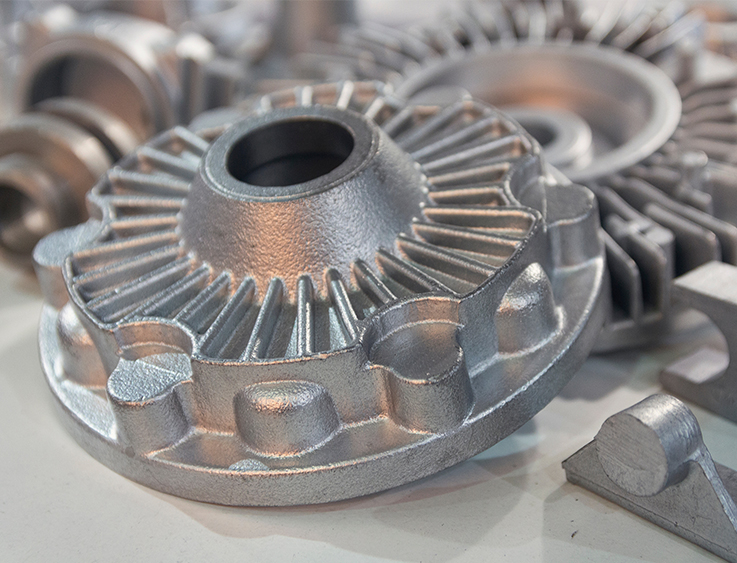

Forging

Through metal forging, the material structure is made tighter, which is suitable for structural parts with high load-bearing capacity and strict strength requirements. Commonly used in the front-end forming of automobiles, motorcycles and industrial parts.

Die Casting

Metals such as aluminum and zinc alloy can be mass-produced by die casting, which is suitable for products with stable dimensions, complex shapes and good surface quality.

Plastic Injection

A fast and highly repeatable process that can accurately replicate plastic parts with complex shapes, widely used in electronics, consumer products and industrial accessories.

Stamping

Suitable for mass production of 2D flat metal parts, such as gaskets, covers, structural plates, etc., with the advantages of fast processing speed and high material utilization.

Powder Metallurgy

Sintering after pressing metal powder into shape is suitable for the production of high-precision parts with magnetic conductivity or mechanical functions, such as gears, bushings, etc.