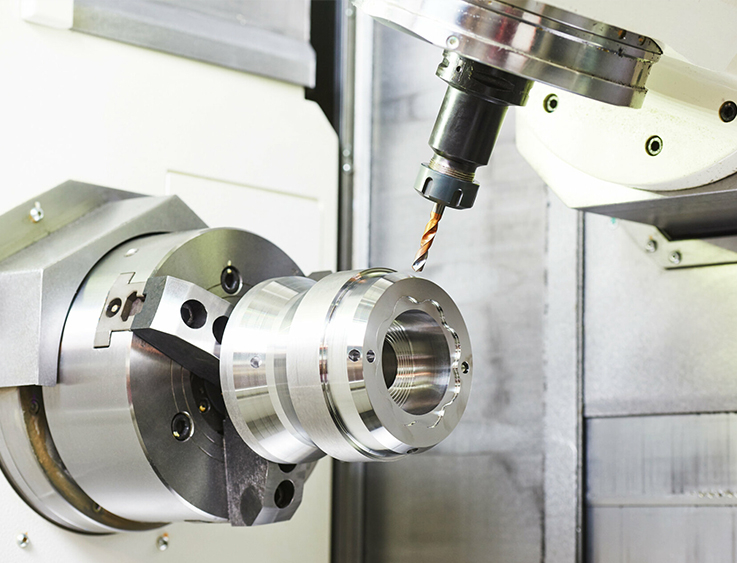

CNC Turning and Milling

Fulong has several high-specification CNC turning and milling machines equipped with dual spindles, dual turrets, power turrets, Y-axis and C-axis active turrets, and supports automatic feeding to achieve continuous production, process integration and high-efficiency processing.

Compared with traditional CNC processing, we can complete the front and back and turning and milling mixed methods in a single machine, greatly reducing the workpiece handling and clamping errors.

The power turret can perform drilling, milling, tapping and other processing. With the dual turrets, dual processes can be performed simultaneously, greatly improving production capacity and processing efficiency.

The power turret equipped with Y and C axes can cope with the needs of complex or asymmetric parts, center offset and multi-angle cutting, ensuring that processing accuracy and efficiency are equally important.

In addition, through standardized tool management and automatic feeding processes, it supports the needs from small-scale and diverse trial production to stable mass production, and is your strong partner to reduce processing risks and accelerate development and listing.

Service Advantages

Dual Spindle

The dual spindle design can complete front and back processing, greatly reduce the number of clamping times and alignment errors, improve dimensional consistency and processing efficiency, and is suitable for workpieces with high requirements for precision and yield.

Dual Turret Synchronous Cutting

The upper and lower turrets can process different processes at the same time, realizing true synchronous processing, greatly shortening the cycle time, and improving processing efficiency and overall production performance.

Power Turret

Supports a variety of processing methods such as turning, milling, drilling, and tapping, and can complete the manufacturing of complex parts in a single machine, reducing equipment conversion and waiting time, and improving efficiency.

Automatic Feeding

With the automatic feeding system, long-term continuous processing and unmanned production at night can be achieved, effectively reducing manpower requirements and ensuring stable production capacity.

Y-Axis and Eccentric Processing

Multi-directional milling, eccentric processing, side holes, slots and non-concentric geometry can be performed, further expanding the complexity of machinable parts.