Precision turns every moment: How Fulong Technology injects innovative energy into bicycle processing

In today’s rapidly evolving and performance-driven bicycle industry, precision is not just an advantage — it’s a necessity. Whether for professional racers or daily commuters, riders expect their bicycles to deliver smooth performance, long-lasting durability, and ergonomic design. Behind the scenes, companies like Fulong Technology Co., Ltd. are redefining the standards of bicycle component manufacturing through advanced CNC machining and innovative production processes.

Shaping the Future of Bicycle Components

From lightweight aluminum frames to high-durability drivetrain systems and high-efficiency braking components, the bicycle industry demands parts that are both lightweight and capable of withstanding prolonged high-stress usage. With years of professional experience and precision engineering expertise, Fulong Technology applies these rigorous standards to every detail of the production process.

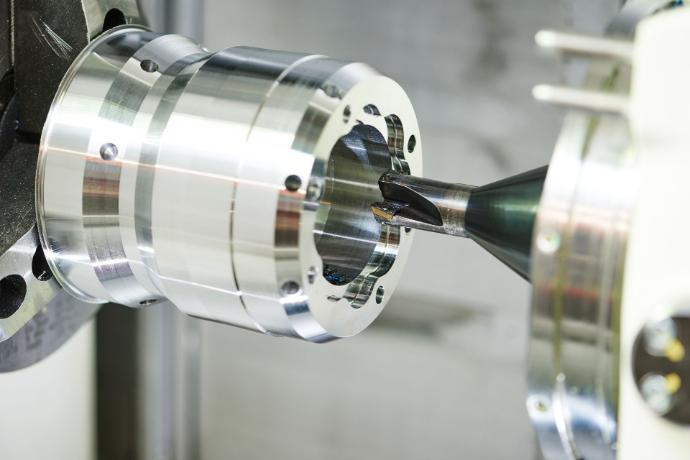

Our CNC milling and turning machines are the core equipment for machining complex components. They are capable of precisely manufacturing a wide range of parts—from frame connectors and hubs to bottom brackets and suspension components—ensuring every piece is produced within extremely tight tolerances.

Delivering Advanced Machining Technology for High-Performance Bicycle

What sets Fulong Technology apart is our ability to integrate multiple machining techniques into a single, highly efficient process. With our CNC turn-mill machines, we can perform both rotational and linear operations in a single setup, significantly enhancing the machining accuracy and production efficiency of multifunctional bicycle components. This streamlined process shortens lead times while meeting the uncompromising quality demands of top-tier brands.

In addition, our broaching capabilities allow for the precise machining of internal geometries—crucial for components such as gear systems and cranksets. Our laser engraving technology provides durable and visually appealing branding and identification marks, designed to withstand harsh environments.

One-Stop Customization and Mass Production Services

Whether you're an emerging bicycle brand developing low-volume prototype parts or a large-scale manufacturer requiring mass production of standard components, Fulong Technology offers complete support. We are equipped to handle both custom small-batch production and high-volume manufacturing, with every process subjected to strict quality control to ensure consistent precision.

We also provide design support services, collaborating closely with clients to transform concepts into production-ready components. Even the most complex designs are brought to life with performance in mind—on both the road and the trail.

Anticipating the Future Needs of a Dynamic Market

With increasing urban mobility and the rise of electric bicycles, the market demand for high-efficiency, lightweight, and durable bicycle components continues to grow. Fulong Technology consistently invests in innovative materials, advanced CNC systems, and smart manufacturing processes to stay at the forefront of industry trends.